CNC – Hot-Wire-Cutter

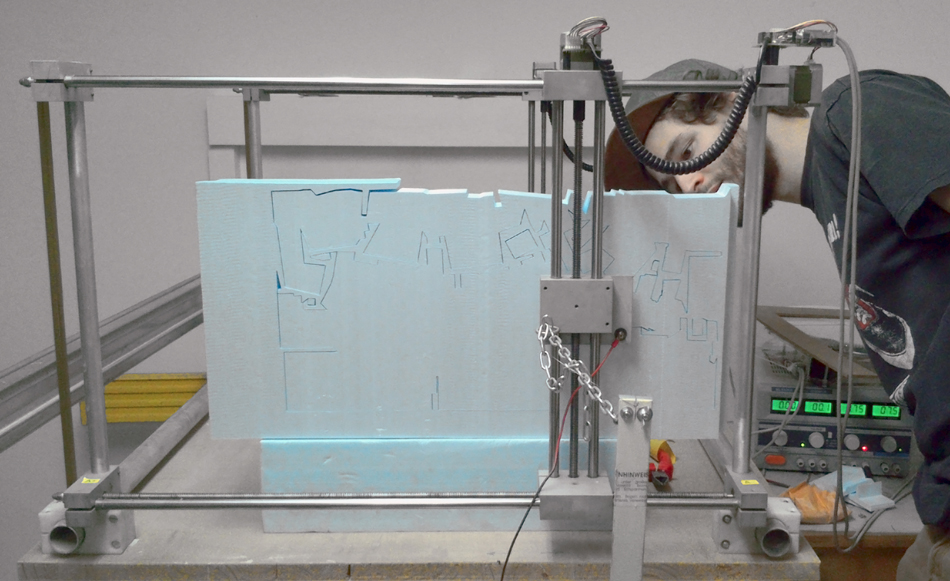

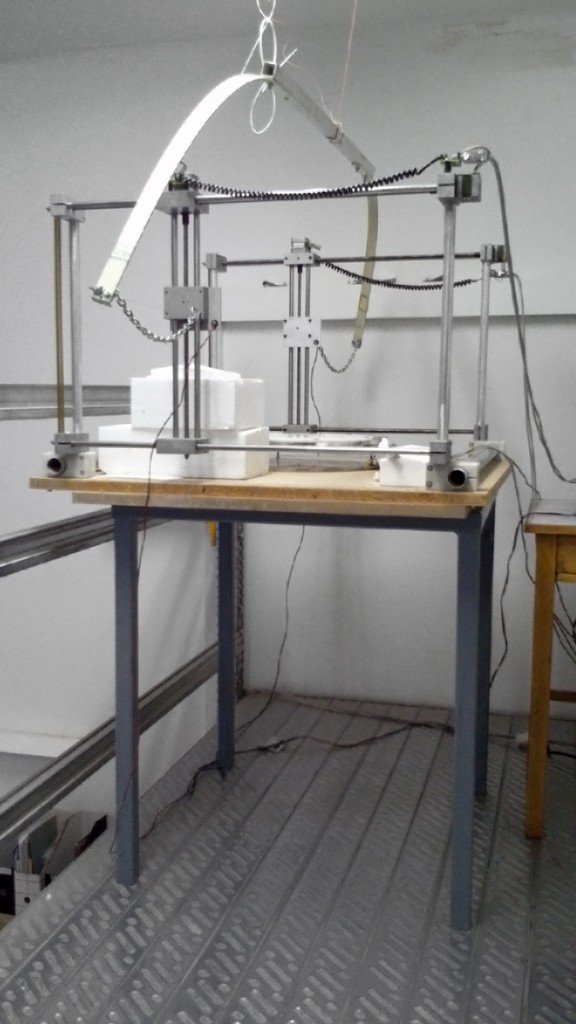

The DDPLab is equipped with one “PC-CUT Standard” machine from StepFour.

The DDPLab is equipped with one “PC-CUT Standard” machine from StepFour.

Originally used for the model-airplane-industry with a cumbersome MSDOS-based cutting software we hacked it to be operated with MACH3.

The gcode now can directly be produced out of Grasshopper an parametric scripting plugin for Rhinoceros 5.0

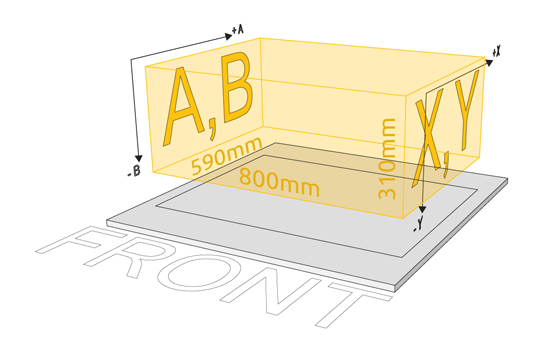

The CNC Hot-Wire-Cutter has a maximum cut volume of 800 x 590 x 310 mm (W x L x H) and all standard heat-isolation foams can be cut.

Basic Grasshopper definitions can be found in the “RESOURCES” section of this webpage.

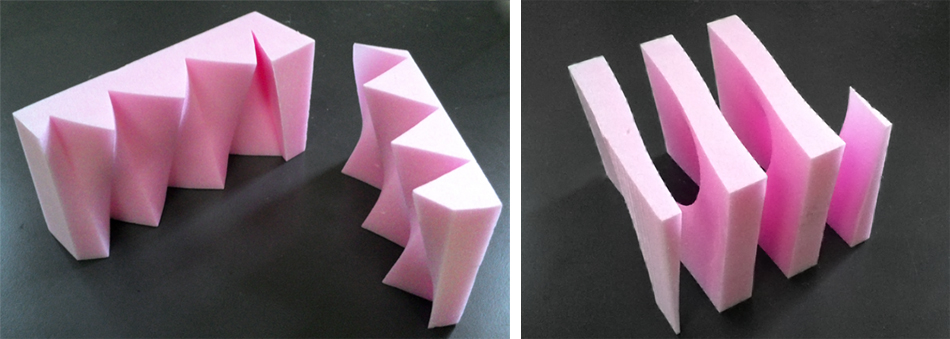

In comparison to milling it is a much faster and less wasteful (material) solution where basic operations like parallel-cutting can be used e.g. to quickly produce building blocks for site models, etc.

________________________________________________________________________________________________________

Besides the 4 axis linear setup we can extend the machine with a 5th axis, a rotational table.

Within this setup we can work with an an extended catalog of ruled surfaces. While the 5th axis establishes another grade of freedom, it also requires a more complex despription of controlling the tool.

Example 1

Synchronized Y and B axis with a constant vertical movement combined with periodic turns of the rotational axis in positive and negative direction.

Example 2

Same setup for the linear axis’s, combined with a continous rotation of the rotational axis.

the gcode for this example would be something like : g1 y-100 b-100 z(7*360)